This is an old revision of the document!

Preventive Action ≠ Risks and Opportunities?

While not mentioned in the original ISO 9001:1987, the term “preventive action” was introduced into ISO 9001:1994. Intended to be a simplistic, yet formalized proactive approach toward addressing “risks”, the new term created a great deal of confusion. This was primarily because the term wasn’t defined in the standard and users rarely purchased ISO 8402:1994, “Quality management and quality assurance–Vocabulary”.

With the release of ISO 9001:2000, ISO 8402 was renumbered and renamed to ISO 9000:2000, “Quality management systems–Fundamentals and Vocabulary”. The definition of “preventive action” is still present in ISO 9000:2015, and has remained unchanged since 1994 as:

preventive action

action to eliminate the cause of a potential nonconformity or other potential undesirable situation

Note 1 to entry: There can be more than one cause for a potential nonconformity.

Note 2 to entry: Preventive action is taken to prevent occurrence whereas corrective action is taken to prevent recurrence.

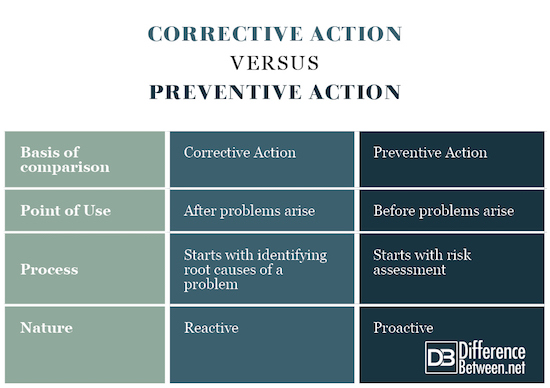

Despite repeated and continued efforts by quality professionals (such as shown below), users continued to confuse corrective action (reactive) with preventive action (proactive).

Compounding the confusion, someone decided to use the same form for both corrective and preventive action (CAPA).

ISO 9001:2015 replaced the concept of “preventive action” with the more expanded “risks and opportunities” (in section 6.1). Upon reading ISO 9001:2015, take note that it repeatedly uses the term “risks and opportunities” as two separate concepts throughout the standard (in sections 4.4f, 5.1.2b, 6.1, 9.1.3e, 9.3.2e & 10.2.1e).

While not defined in ISO 9000:2015 or ISO 9001:2015, the term “risks and opportunities” is defined in ISO 14001:2015, “Environmental management systems — Requirements with guidance for use”.

ISO 14001:2015

3.2.11 risks and opportunities

potential adverse effects (threats) and potential beneficial effects (opportunities)

Interestingly, while a definition for “risk” was added to the ISO 9000:2015, “Quality management systems–Fundamentals and Vocabulary”. Unfortunately, ISO struggles with properly defining the word “risk” (Ref.: A Matter of "Risk"). Regardless of how ISO 9000:2015 defines “risk”, ISO 14001:2015 makes it clear that “risks” are “threats”. So, for the sake of simplicity, let's use the definition contained in API Spec Q1, "Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas Industry" (Ninth Edition, June 2013), published by the American Petroleum Institute (API).

API Spec Q1

3.1.19 risk

Situation or circumstance that has both a likelihood of occurring and a potentially negative consequence.

Is the use of "Preventive Action" still valid?

While many organizations continue to use the term “preventive action” to address “negative risks“/threats (e.g., because it was embedded into their corrective action forms, databases, etc.), it fails to address “positive risks” and “opportunities”.

Even though use of “preventive action” is still permitted to address “negative risks”/threats, many ISO 9001 and AS9100:2016 registrars are encouraging their clients to eliminate use of the term “preventive action” and adopt the term “risks and opportunities” to ensure that “positive risks” and “opportunities” are also addressed within their QMS.

A reason for this preference can be found in ISO JTCG N359, “JTCG Frequently Asked Questions in support of Annex SL” (dated 2013-12-03), explaining why the concept of “Preventive Action” was replaced with “risks and opportunities”.

“JTCG Frequently Asked Questions in support of Annex SL”

10. Why does the common text not include a specific clause on “Preventive Action”?

The high level structure and identical text does not include a clause giving specific requirements for “preventive action”. This is because one of the key purposes of a formal management system is to act as a preventive tool. Consequently, a MSS requires an assessment of the organization’s “external and internal issues that are relevant to its purpose and that affect its ability to achieve the intended outcome(s)” in clause 4.1, and to “determine the risks and opportunities that need to be addressed to: assure the XXX management system can achieve its intended outcome(s); prevent, or reduce, undesired effects; achieve continual improvement.” in clause 6.1. These two sets of requirements are considered to cover the concept of “preventive action”, and also to take a wider view that looks at risks and opportunities.

However, this presents challenges because other industry standards, such as ISO 13485:2016, “Medical Devices — Quality management systems — Requirements for regulatory purposes”, ISO 17020:2012, “Conformity Assessment — Requirements for the operation of various types of bodies performing inspection” (Option A) and AAR M-1003:2019, Section J, “Specification for Quality Assurance”, and API Spec Q1, "Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas Industry" (Ninth Edition, June 2013), all specifically require “preventive action” to be included in the QMS.

Conclusion

An organization can certainly continue to use “preventive actions” as a methodology within its QMS for addressing “negative risks”/threats PROVIDED that the organization also has a separate methodology of addressing “positive risks“ and opportunities.

Supporting this, there is nothing stated in either the ”ISO/TC 176/SC 2 Listing of Approved Interpretations against ISO 9001:2015“ or ”US TC 176 - TG22 - Interpretations“ forbidding or restricting use of the “preventive action” methodology. And ISO 9000:2015 continues to recognize “preventive action” as a legitimate methodology (Ref. ISO 9000:2015, sec. 3.12.1).

HOWEVER, I recommend eliminating the use of this confusing term because it is so widely misunderstood. A MUCH better way to approach this topic is through the implementation of actual risk management tools (which is what ISO 9001:1994 should have required) incorporating the use of FMEAs (Failure Modes and Effects Analysis. A FMEA should be completed for each process (aka PFMEA - “Process Failure Modes and Effects Analysis”) and design (aka DFMEA - “Design Failure Modes and Effects Analysis”).