Table of Contents

5S - Information (and Resources/Tools for Implementation)

Does your business look like a candidate for an industrial version of the TV show “Hoarders”? Are work areas cluttered and unorganized?

Implementing 5S can solve those problems.

5S is a well-established and proven systematic methodology for improving efficiency (e.g., through better utilization of space & equipment availability), productivity, quality, and safety. Speaking in Lean Six Sigma terms, 5S helps to reduce non-value-added time (e.g., searching for the correct tools/fixtures) while also reducing costs.

What is 5S

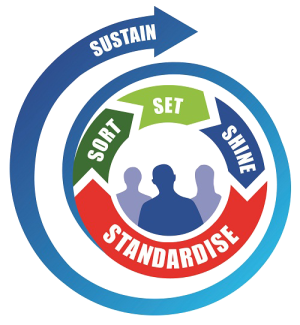

5S uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated for English-speaking users as: “sort”, “set in order”, “shine”, “standardize”, and “sustain”.

| S | Meaning |

|---|---|

| Sort | Sort through and sort out junk, seldom-used items and necessary items. |

| Set | Set locations; use boundaries & addresses to assure recoil. |

| Shine | Clean and paint and clean regularly. |

| Standardize | Define and standardize work processes, activities, and tasks. |

| Sustain | Institutionalize 5S throughout the organization & audit compliance to ensure ongoing effectiveness. |

While 5S is often graphically represented as an iterative cycle… I've never seen it applied as such. I suspect because a continuous cycle doesn't make sense in a practical application. Instead, it would be more accurately represented as a spiral that spins off in the “Sustain” mode (as shown to the above right - which I “believe” was created by Mr. Graham Cripps).1) After all, the first 4 steps in the process would not need to be repeated unless (or until) the process was changed (e.g., improved).

In his article, "LOST TREASURE: Ford’s original philosophy of ‘CANDO’" Ravindranath Pandian notes that attempts to find single word labels equivalent to those five Japanese words have mostly failed, due to linguistic challenges. Such translators have worked hard to find words that begin with the letter S, a poor strategy. However, sans poetic brevity, fuller explanations of each Japanese word in 5S using a few lines of text, have conveyed their original meaning.2)

Michel Baudin provides the following are translations of the original five S's, to the best of his ability:

| S | Meaning |

|---|---|

| Seiri (整理) | does not mean Sort. In everyday Japanese, it means to sort out, as in resolving administrative problems. In 5S, it means removing from the shop floor the items you don’t use routinely. |

| Seiton (整頓) | does not mean Set in order. In everyday Japanese, it means arranging neatly. In 5S, it refers to having assigned locations and labels for everything you retain on the shop floor. |

| Seiso (清掃) | means Clean, not Shine. The idea is to have production operators clean their own workplaces at shift end, so that they notice details like spills, frayed cables, or broken lamps. It is not about making them pretty. |

| Seiketsu(清潔) | does not mean Standardize. In everyday Japanese, it is a noun meaning cleanliness. In 5S, it is the reduction of the first three S’s to daily practice by management enforcement, through things like checklists, assignment of responsibility for daily housekeeping activities, and routine audits. |

| Shitsuke (躾) | does not mean Sustain. In everyday Japanese, it is a noun, meaning upbringing. It is not an action but the condition you reach when the performance of the first three S’s has become second nature to the organization. As long as you tell your kid to brush his teeth every day, you are practicing Seiketsu; once he does it without prompting, you have achieved Shitsuke. |

Getting Started

The best way to start a 5S program is through informing personnel in what “5S” is, your intention to implement 5S, inviting their participation in the process, and providing them training in the basics of 5S.

There are a large number of 5S training videos available on YouTube.

People working in the targeted areas usually have some fantastic ideas to address the “low hanging fruit” (problems easily solved). To expand their ideas beyond the simple improvement, they will need to be trained in the resources available to them. For example, availability and use of “Visual Work Place” resources, such as shadow boards, color-coded and labeled floor tapes, etc. to maximize the 5S efforts.

Free 5S Resources

Graphic Products offers a number of free booklets, articles and videos explaining 5S. These all include examples of how to use their products to quickly and effectively implement 5S in yiour facility.

Brady ID also offers free Lean/5S resources (with examples). Such as their:

And videos… such as:

5S Audits

After implementation, sustainment should be confirmed through regularly auditing every area of the 5S program. This can be done weekly, monthly, or, once firmly embedded into the company's culture, annually. 5S audits are sometimes included as part of the Quality Management System (QMS) internal audits.

Muda Masters offers several free 5S Audit Templates (i.e., Checklists).

5S Checklist for the Office

https://citoolkit.com/wp-content/uploads/templates/5s_audit_checklist_offices.pdf

History of 5S

5S actually began in the USA as “CANDO”. Developed by Henry Ford (probably prior to 1920). CANDO is an acronym for five steps:

C = Cleaning up

A = Arranging

N = Neatness

D = Discipline

O = Ongoing improvement

Some people (often working with theory rather than application) prefer the CANDO acronym in the familiar (albeit rarely actually utilized) iterative cycle graphic image. However, based upon application & observation, I maintain that “Sustain” is more appropriate.

In his book “Today and Tomorrow” (1926), Henry Ford wrote:

The first job was to clean up — that is always the first thing to do in order to find out what you are about. We cannot afford to have dirt around — it is too expensive. Everything is painted and kept painted a light color, so the least bit of dirt will show. We do not paint to cover up dirt — we paint white or light gray in order that cleanliness may be the order of things and not the exception.

After WW II, Japan was eager to learn from America. Notably, a team from Toyota visited Ford in 1950. The team was awed by the scale of Ford. Toyota produced only 40 automobiles per day while Ford produced 8,000 a day! Toyota decided to adopt American automobile mass production methods with a few changes. A Toyota team was trained at Ford. In 1956 Taiichi Ohno, the company’s chief engineer visited Ford and the Piggly Wiggly supermarket chain. Based on those observations, Taiichi Ohno and Eiji Toyoda along with some Japanese industrial engineers, began developing 5S as part of the “Toyota Production System” (TPS). After some improvements to the system, Sakichi Toyoda (Father of the Japanese industrial revolution) and his sons Kiichiro and Taiichi Ohno named it “5S”.3)