Table of Contents

How a QMS is different from a "Certified Management System"

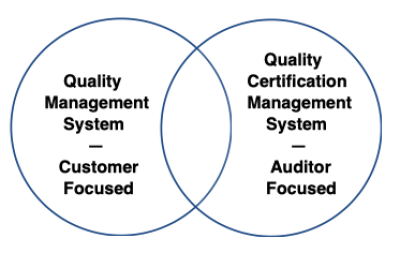

EVERY company in a free market economy has a QMS (Quality Management System). Whether formal or informal and regardless of the degree to which it is documented, it exists because management views it as adding value. This QMS likely existed prior to the company ever becoming aware of ISO 9001 (or AS9100). We know this because if the company didn’t have any sort of QMS, customers would take their business to competitors and it would (eventually) cease to exist! I'll refer to this QMS as the “actual” QMS.

A “Certification Management System” (usually maintained by one or two key people) is developed, implemented, and maintained for the sole purpose of obtaining and retaining QMS Certification from an accredited Certification Body (CB). The value in obtaining a QMS Certification is to:

- Satisfy Customer “Supplier Qualification” requirements;

- Achieve a “Preferred” supplier status for achieving the “QMS Certification”;

- Market to customers who perceive value in the “QMS Certification”.

While these two systems overlap, the “actual” QMS operates independently of any “QMS Certification” status. The primary difference between these systems is that the “actual” QMS is “Customer Focused” while the “Quality Certification Management System” is “Auditor Focused”.

Here are some indicators that this dual system is in place:

- Rather than referring to its documented Quality Management System as simply a “QMS”, the company will literally attach the identification of the standard for which it is being “certified” as a prefix. For example, it's “ISO 9001 Quality Management System” or “AS9100 Quality Management System” (tacitly acknowledging the dual systems in place).

- If a key person managing the “QMS Certification System” leaves the company, the business will struggle during its next external audit because there is no one managing the “QMS Certification System”. However, the outgoing quality usually remains unchanged because the “actual” QMS is still functioning as usual.

- In some cases, the person managing the “QMS Certification System” has the identification of the standard embedded in their title (e.g., ISO 9000 Manager, ISO 9000 Systems Director, ISO 9000 Administrator).

- Not promoting (or poorly promoting) their registration (e.g., on their website)

Why do they do this?

The answer is simple… the company sees little value in ISO 9001 OTHER than satisfying a customer requirement (or expectation) for them to hold an ISO 9001 (or AS91xx) Certificate from a CB.

When customers stop demanding their suppliers to hold an ISO 9001 (or AS91xx) Certificate from a CB, the companies tend to surrender their certifications. With that “value” now gone, there is no longer justification for the added cost of maintaining a “Certification Management System”.

This is NOT to say that those companies no longer have a QMS… or allow it to languish. On the contrary, the “actual” QMS (mentioned above) remains in place because management views it as adding value.

Doesn't ISO 9001 / AS91xx improve Quality?

Whether ISO 9001, AS91xx, or any other QMS Standard improves your “actual” QMS depends on the level of maturity and sophistication of your “actual” QMS. Remember, ISO 9001 is an “entry-level” QMS Standard intended to improve companies with an extremely basic, immature QMS producing poor or inconsistent results.

Companies with very mature and sophisticated quality management systems (e.g., using Lean Six Sigma & TRIZ) would not benefit at all from implementing ISO 9001 or AS9100. In fact, ISO 9001, AS9100, and many other QMS Standards actually promote some flawed, antiquated concepts.

But our customers demand we hold a QMS Certification...

When companies have a sophisticated QMS, and customers demand that they also hold a QMS Certification, this presents some interesting challenges. For example, the company must have personnel who are able to:

- Effectively defend & justify its interpretation and application of the standard; and

- Educate the external auditor(s) as to “how” the more modern tools satisfy the requirements of the standard.

Auditor Interpretation

While virtually every standard contains some degree of subjectivity, ISO 9001:2015 is exponentially more subjective than ISO 9001:1994. Consequently, the results of an audit today depend far more upon how the Auditor interprets those subjective requirements. It is commonplace for a company to successfully complete an audit with no non-conformities under one Auditor; while receiving multiple non-conformities from a different Auditor the following year… with no changes having been made to their QMS!

Having personnel with the knowledge, skills, and experience to effectively communicate and defend the company's justification of its interpretation and application of the standard has become an essential element of QMS Certification Management.

Auditor Competence

ISO 9001:2015 was designed to be both simple (entry-level) and generic. However, many of the ISO 9001 & AS91xx auditors still rely on outdated information to interpret the standard. While these ISO 9001 & AS91xx Auditors may have been extremely competent 30 or 40 years ago, they are often ill-equipped to interpret and apply the requirements of ISO 9001 & AS91xx to a company that has implemented more modern concepts… such as Lean Six Sigma. And the vast majority of these Auditors have never even heard of Apollo Root Causes Analysis or TRIZ.

Case-in-point, I heard one experienced Aerospace Auditor state: “I don't care how much Lean Six Sigma a company has, it's not going to make them a better company.” This is an appalling level of Auditor knowledge in current quality tools and techniques.

I've witnessed multiple Auditors complain, and even issue nonconformities, simply because they did not understand the logic of how the company had interpreted and applied the standard. While these invalid nonconformities should be appealed, far too many companies lack personnel with the knowledge, skills, and ability to submit a proper appeal to the CB.

If you’re ready for a path forward now…

If you’re ready for a path forward now…

Just click here to schedule your FREE Certification Strategy Meeting (via Zoom) with me. I’ll answer any questions you might have. No sales pitch. Just information.

Or, for my cell phone & e-mail address, visit the contact us page.

100% of our clients achieve certification on their first attempt.

This means that no CB has ever required a “follow-up” or “special” audit for any of our clients prior to being issued their certification.

We provide you with “peace of mind” that we'll take care of QMS certification!