Table of Contents

Continuous Improvement... and TRIZ

While the term “Continuous Improvement” is thrown around with reckless abandon, I find that few quality professionals have a good understanding of it. While most QMS (Quality Management System) standards promote… or even require continuous improvement, none of them offer any suggestions as to how to go about this. It is entirely possible that the authors of these standards lack a basic understanding of what continuous improvement actually involves.

How to do CI Wrong

Most CI projects begin with ambiguous / poorly defined objectives. For example, to “improve the efficiency” of a specific process.

Next, a CI “team” is assembled, and a “Team Leader” is assigned. Usually, no one on the team has any “real” critical thinking abilities or problem-solving skills because no formal training in problem-solving was specified or required to be on the team.

Left to their own limited knowledge or basic experience with similar activities, the teams tend to gravitate to the most basic and inefficient “idea-sourcing” methods known. These include utilizing unstructured thinking methods such as:

- Brainstorming

- Crowdsourcing

- Mind Mapping

At this point, the word “team” becomes a misnomer because each individual is submitting their own biased ideas based on their limited experience(s) or worse… their “intuition”. This results in a large number of low-quality “ideas”.

The problems (so far) with this form of CI are:

- the process began without identifying a specific problem that needs to be solved;

- with no specific problem identified, no specific metrics were identified & established to assess the degree to which any improvements had been realized as a result of any changes;

- no analysis or problem-solving methodologies were taught prior to forming the team;

- Since no specific problem was identified, the team focused on “Idea-Sourcing” rather than “Solution-Sourcing”.

If you're familiar with Lean Six Sigma, you will recognize the first two problems as being addressed in the “Define” & “Measure” steps in the DMAIC process. However, for the “Analyze” and “Improve” portions of the DMAIC process I will be referencing both “Cause & Effect Chain” (CEC) analysis & TRIZ.

A large number of Quality Professionals (typically those either unfamiliar with or rejecting Lean Six Sigma) actually believe that if a sufficient “Root Cause Analysis” (RCA) is performed (e.g., 5 Whys, Ishikawa/Fishbone charting, Apollo Root Cause Analysis, Fault Tree Analysis), then the solution to a problem will be obvious. This approach has multiple flaws. The most obvious is that the user must ignore the teachings of Walter Shewhart & W. Edwards Deming by ignoring (or denying the existence of) “Common Cause” variations in a process. This is akin to ignoring the laws of physics.

These misperceptions persist because many problems are the result of poorly designed processes containing multiple “Assignable Cause” variations that are simple, easily observed, and have obvious solutions. These types of problems are typically referred to as “low-hanging fruit” because they're so easily addressed. Simply understanding the cause of a significant problem does not magically spark innovation to find an adequate solution.

However, “Cause & Effect Chain” (CEC) analysis (a term recognizing that there may not be an “assignable cause”) does hold value in the problem-solving process.

Other well-established analysis tools with Lean Six Sigma include, but are not limited to:

- Value Stream Mapping

- Spaghetti diagrams

- Pareto analysis

- Bar charts

- Trend charts

- Cpk Charts

- Sigma Charts

- Histograms

- Scatter Diagrams

- Control Charts

Risk Mitigation & Countermeasures ARE Improvements

Due to their obsession with RCA and “corrective action”, traditional Quality Professionals (relying entirely on legacy concepts) rarely comprehend that the primary purpose of any robust QMS is to establish “controls”, throughout the complete/entire value stream, to identify and eliminate, or mitigate, risks to consistently fulfilling all agreed requirements and established expectations (commitments) relating to the provision of products and/or services.

This means that risk management tools, such as FMEAs, Risk Matrices, etc. are completely valid CI tools.

Before a process can be improved, it must first be standardized. This typically means detailing how the process flows (e.g., using flowcharts), along with standardized procedures, work instructions, infographics, etc. providing consistent instructions to workers within the process, and formalized training of workers (to ensure that personnel working in a process are competent to work independently). These are all risk controls.

Before a process can be improved, it must first be standardized. This typically means detailing how the process flows (e.g., using flowcharts), along with standardized procedures, work instructions, infographics, etc. providing consistent instructions to workers within the process, and formalized training of workers (to ensure that personnel working in a process are competent to work independently). These are all risk controls.

EVERY Inspection point is a “risk control”. Inspections are performed because the process is not reliably producing consistent conforming products. Quite often, once an Inspection point is established in a Work Router/Traveler, it remains despite improvements in the process. Performing a Pareto analysis of the types of defects that an Inspection point is detecting will indicate which portion of the process is producing nonconformities. THAT should be the focus of a CI project.

If the CI project eliminates the non-conformities, then the Inspection point can be eliminated. However, if there are “Technical Contradictions” (discussed later), then (1) Inspections should be limited to only those characteristics regularly found to be non-conforming, and (2) the Inspection point may need to be moved closer to where the nonconformities are being produced (at an optimal point in the production process flow).

Countermeasures

Another misunderstood concept is “countermeasures”. A “countermeasure” is any action taken to counteract, negate, neutralize, or offset the effects of an undesirable event.

A “countermeasure” is employed where the complete elimination of circumstance, that could lead to one or more potential nonconformities, is impossible or improbable due to the nature of a process (i.e., common cause variations). Unlike a “corrective action”, which eliminates the “root cause” of nonconforming conditions (i.e., special cause variations), the purpose of a “countermeasure” is to counteract, negate, neutralize, or offset the effects of a known variation occurring randomly in a process. Some monitoring systems are designed to detect trends, allowing countermeasures to be executed at predetermined set points prior to the process producing nonconforming products/services (e.g., control/feedback loops).

One of the best everyday examples is the guardrail alongside highways. Other examples include:

- "Explosive Reactive Armor" (ERA) on military tanks;

- Chaff and flares used by military planes and helicopters to help evade a missile attack, and

- The pole that was welded on the front of US Jeeps during WW II.

The Optimization Wall

Let's assume that the above problem was well defined (with boundaries) and key metrics identified. Data was collected and the team above was trained in basic “Cause & Effect Chain” (CEC) analysis. Without having been trained in TRIZ, these teams often fail to ensure that no technical contradictions exist.

Technical Contradiction

Source: “Glossary of TRIZ and TRIZ-Related Terms” (Version 1.2) by Valeri Souchkov, “The International TRIZ Association – MATRIZ, 2018” http://www.xtriz.com/publications/TRIZGlossaryVersion1_2.pdf)

Teams often celebrate success in achieving an improvement in one area of a process while completely ignoring that one or more other areas within that same process were degraded as a result. This is easily observed in a Pareto chart depicting the entire process. When one area is improved, one or more other areas within that same process were degraded as a result. While this may be a preferred trade-off, it indicates a technical contradiction… which is often indicative of a technical limitation (e.g., the process has reached the limits of its capabilities). If the process is “state-of-the-art”, no further improvements may be possible… until advancements in other areas produce improvements in this technology.

TRIZ

While most books on TRIZ focus on design, the key takeaway for modern Quality Professionals is, rather than focusing on “repairing” a process, to look at the problem and ask “What would be the ideal state?” This would often involve including Engineering personnel in the CI process. For example,

- Are there multiple parts that could be fabricated, molded, or stamped to form a single part (simplifying and error-proofing a step in the assembly process)?

- Are there common parts (e.g., fasteners) that could be standardized (reducing the number of different part numbers)?

- Are there components that can be bypassed or are no longer needed?

An example of TRIZ can be seen in the evolution of the radio. When radios first appeared, the signal had to be manually adjusted for optimal reception.

Then, during the mid-twentieth century, there was a technological breakthrough. Automatic Frequency Control (AFC), also called Automatic Fine Tuning (AFT), was introduced allowing the radio circuitry to automatically keep a resonant circuit tuned to the frequency of an incoming radio signal. It was primarily used in radio receivers to keep the receiver tuned to the frequency of the desired station.

AFC was needed because, after the bandpass frequency of a receiver is tuned to the frequency of a transmitter, the two frequencies can drift apart, interrupting the reception. This can be caused by a poorly controlled transmitter frequency, but the most common cause is drift of the center bandpass frequency of the receiver, due to thermal or mechanical drift in the values of the electronic components.

Using the technology available at that time, this “optimized” the radio tuning process.

During the 1970s, there was another technological breakthrough. Receivers began to be designed using frequency synthesizer circuits, which synthesized the receiver's input frequency from a crystal oscillator using the vibrations of an ultra-stable quartz crystal. These maintained sufficiently stable frequencies that AFCs were no longer needed.

At that point, the radio tuning process had been “optimized” using the available technology.

There are constant advances in virtually every sector. Consequently, a review of advances in technology should be included as a part of the CI process.

To learn more about TRIZ, I recommend reading:

Prior to initiating a CI Project, ALWAYS check with Engineering to ensure that the current product(s) isn't about to undergo a major change/revision that would impact the production process. Similarly, ensure that existing product(s) isn't scheduled to be discontinued.

TRIZ: Levels of Innovation

A HUGE barrier to improvement is “technical contradictions” (mentioned earlier). These are limitations or barriers encountered when using traditional improvement approaches and tools. To overcome “technical contradictions”, we need a new set of tools.

TRIZ consists of 5 levels of innovation

- Quantitative improvement of the existing function/principle (e.g., to reinforce a building, its walls are made thicker).

- Qualitative improvement of the existing function/principle (e.g., merging an alarm clock and CD player).

- Extending a known function/principle combination to a new market (e.g., extending the function “to see through”, based on the principle “x-ray emission” from medical purposes (medical market) to different applications within different markets, such as non-destructive testing).

- Creating a new function/principle combination (e.g., the first radio transmitter or Ebay.com).

- Discovering a new principle (e.g., through creating new scientific knowledge, such as x-rays or the photovoltaic effect).

For example, the Stirling Engine, invented over 200 years ago, is finding new applications/markets (as a Level 3 Innovation).

How a Single Swedish Submarine Sank a US Aircraft Carrier

How the Stirling Engine actually works in a submarine

More: Modern Uses of Stirling Engines

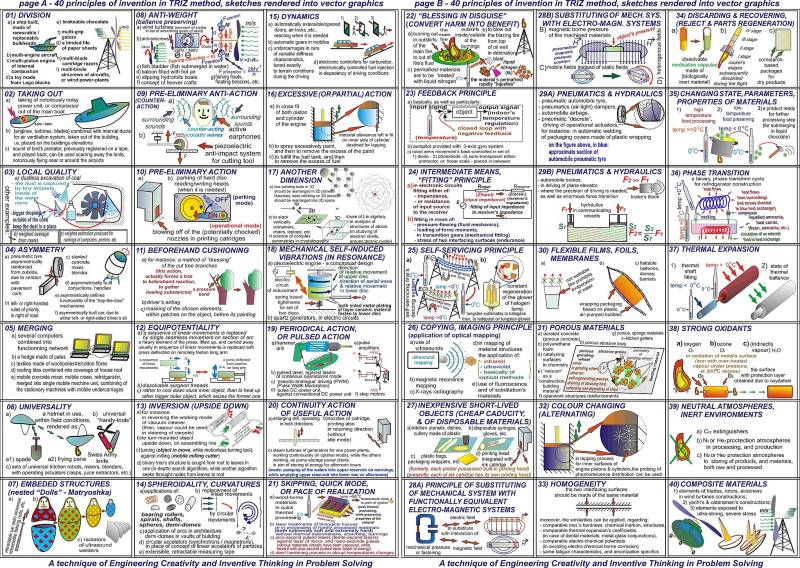

To “spark” these types of innovative improvements, TRIZ practitioners utilize the “40 principles of TRIZ”:

https://commons.wikimedia.org/w/index.php?curid=45719323