Table of Contents

Value Added Audits

Contrary to the better-known audits that focus on verifying “compliance” with procedures, a “Value-Added Audit” focuses on improvement through the elimination or reduction of non-value-added (NVA) activities/steps in a process. Ultimately, enforcing compliance with ineffective/inefficient procedures simply reinforces and perpetuates ineffective/inefficient processes… with little or no regard to improving the process. In contrast, a Value-Added Audit focuses on questioning whether each activity/step is actually necessary in order to satisfy customer requirements.

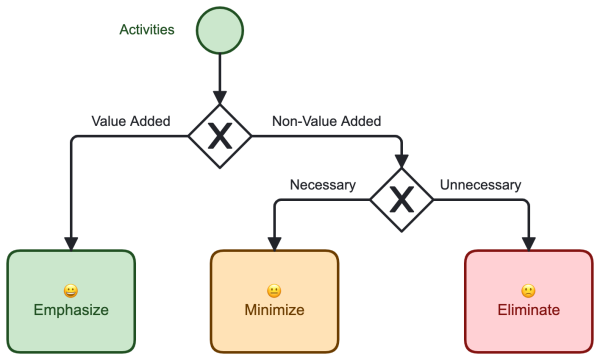

During a “Value-Added Audit the auditor examines each activity/step in a process to categorize each individual process step as a:

- Value Added (VAA) Activity

- Necessary Non-Valued Activity (NNVA)

- Non-Value Added (NVA)

Value-Added Audits are far more popular amongst Lean Six Sigma (LSS) companies than ISO 9001 / AS9100 companies. However, Value-Added Audits coupled with the use of LSS tools present an untapped opportunity for ISO 9001 / AS9100 companies to experience significant improvements. However, for best results, companies should utilize auditors who are Lean Six Sigma certified Green Belts.

While it is a bit outdated, one of the best books describing these audits is ”Understanding and Applying Value-Added Assessment - Eliminating Business Process Waste“ by William E. Trischiler.

Definitions

Value Added Activities

Those activities that change the fit, form, or function of the item going through the process of transformation. VA work takes the input and turns it into something of value to your customer — something they are willing to pay you for.

The “output” includes ALL deliverables… which may include products/services, Certificates of Conformance, Certificates of Analysis, User Manuals, etc.

Necessary Non-Valued Activities (NNVA)

Activities that are absolutely necessary to complete work with the present operations and/or equipment. These activities do not add value to the customer but must be performed in order for the process to produce products and/or services that satisfy customer requirements.

NNVAs typically “support” the “core” process(es), and typically includes activities such as purchasing, calibration of Measuring and Test Equipment (M&TE), equipment maintenance, training and/or qualification of personnel, etc.

Non-Value Added (NVA)

Any action that does not add value to a product or service (value being defined by the customer) and is not necessary for the company to produce products/services satisfying customer requirements. NVA is the waste within a process.

The eight lean manufacturing wastes, mostly derived from the TPS (Toyota Production System), have a universal application to businesses today. The acronym for the eight wastes is DOWNTIME.

Preparing for a Value-Added Audit

Performing a Value-Added Audit requires a detailed understanding of a company's “core” processes (those processes directly transforming inputs into outputs that are deliverable to the customer). A detailed flowchart (preferably a BPMN flowchart) is essential. While not ideal, text-based instructions/procedures may be used.

Performing a Value-Added Audit requires a detailed understanding of a company's “core” processes (those processes directly transforming inputs into outputs that are deliverable to the customer). A detailed flowchart (preferably a BPMN flowchart) is essential. While not ideal, text-based instructions/procedures may be used.

Flowcharts are often superior to text-based instructions/procedures alone because flowcharts are event-driven. Text-based instructions/procedures often omit certain events that occur within the process. However, a Flowchart is often supported by text-based instructions/procedures that describe the conditions leading to specific events that, in turn, dictate specific activities.

Consequently, it may be necessary for the auditor to create a flowchart prior to beginning the Value-Added Audit. While it is tempting to begin making changes to a process while creating a flowchart, the flowchart should accurately reflect the “Current State” of the process. The Value-Added Audit will be categorizing those activities as VAA, NNVA, or NVA.

After performing a Value-Added Audit of the “core” processes”, the “supporting” processes should also be audited to differentiate the NNVA from the NVA activities.

Performing a Value-Added Audit

Using the flowchart(s) and any other detailed information pertinent to the process, the auditor should begin examining each individual step in the sequence of the process—evaluating and categorizing each step as a:

- Value Added (VAA) Activity

- Necessary Non-Valued Activity (NNVA)

- Non-Value Added (NVA)

When using hard copy (paper) flowcharts, a common technique is to use different color highlighters to categorize each activity. When using a computer or tablet, many flowcharting software programs allow the user to change the color of the symbols. Obviously, there should be a “key” linking each color to the category that the activity has been assigned.

A Value-Added Audit can focus on ANY portion of a process. It doesn't necessarily need to start at the beginning of the process. In fact, when mature processes are evaluated, it is more typical to see the Value-Added Audits focus on specific portions of the process (to make small refinements to the process over time).

Post Audit Analysis

Upon completion of the Value-Added Audit, the auditor(s) should confer with the process owner and any SMEs (Subject Matter Experts) to confirm the results. Some activities may need to be re-categorized. In many cases, the analysis will reveal improvement opportunities that can be realized by changing the process flow.

As this process matures, there may be justification for further analysis. For example, the creation of “Value Stream Maps” capturing data such as Takt Time, creating Spaghetti Diagrams (to calculate the distance that the product travels during the process - as transportation is a form of waste… and every time that a product is touched or moved is an opportunity for the introduction of defects (e.g., scratches, scrapes, dents), etc.

Improvement

Upon completing the analysis, any improvements identified should be included in an updated flowchart (Future State). Upon approval of this process change (by the process owner), it is the responsibility of the process owner to institute the change(s).

Ideally, any metrics captured before the change should be compared to data being realized after the change(s) are in place.

This article is a very simplistic overview of the Value-Added Audit process. To realize more significant improvements would necessitate implementing a Lean Six Sigma program within the company, incorporating tools such as the DMAIC process. And eventually, incorporate actual “problem solving” tools such as those found in TRIZ.