This is an old revision of the document!

Human Factors

While not specifically mentioned in ISO 9001:2015 (other than a awkwardly written “Note” under sec. 7.1.4), AS 9100 requires:

While not specifically mentioned in ISO 9001:2015 (other than a awkwardly written “Note” under sec. 7.1.4), AS 9100 requires:

10.2 Nonconformity and Corrective Action

10.2.1 When a nonconformity occurs, including any arising from complaints, the organization shall:

b. evaluate the need for action to eliminate the cause(s) of the nonconformity, in order that it does not recur or occur elsewhere, by:

2. determining the causes of the nonconformity, including, as applicable, those related to human factors;

However, ISO 9001 does require:

8.5.1 Control of Production and Service Provision

Controlled conditions shall include, as applicable:

g. the implementation of actions to prevent human error;

What are Human Factors?

I find that AS 9100 clients (and many AS 9100 auditors) have difficulty understanding “human factors”. And I typically mention the availability of the FAA “Dirty Dozen” Human Factors. You can download this 2-page PDF from: https://www.faasafety.gov/files/gslac/library/documents/2012/Nov/71574/DirtyDozenWeb3.pdf

| The FAA “12 Common Causes of Human Factors Errors” publication includes: | |

|---|---|

| 1. Lack of Communication | 7. Lack of Resources |

| 2. Complacency | 8. Pressure |

| 3. Lack of Knowledge | 9. Lack of Assertiveness |

| 4. Distractions | 10. Stress |

| 5. Lack of Teamwork | 11. Lack of Awareness |

| 6. Fatigue | 12. Norms |

Since human factors are mentioned in AS 9100, sec. 10.2, many assume that it is required to eliminate root causes associated with human factors. In the vast majority of cases, this is not true. I recommend reading the AMT (FAA “Aviation Maintenance Technician”) Handbook because it clearly emphasizes/focuses on Risk Mitigation (rather than corrective action) when managing human factors.

The AMT Handbook: Chapter 14, Human Factors, can be downloaded from: https://www.faasafety.gov/files/gslac/courses/content/258/1097/AMT_Handbook_Addendum_Human_Factors.pdf

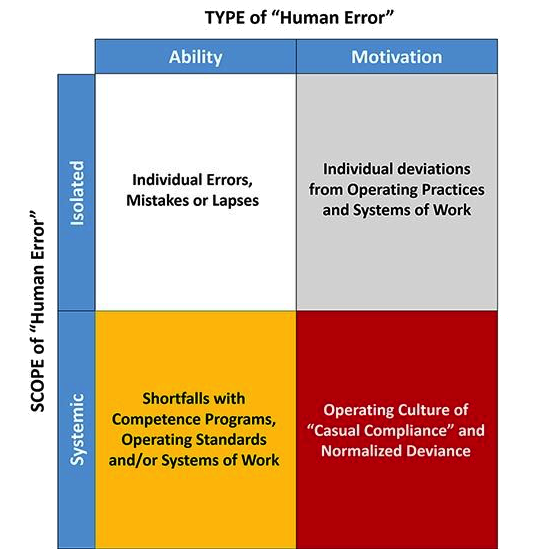

There is also a quadrant tool (similar to a SWOT) for determining the “scope” & “type” of human errors observed (from the article: "Human error & operational risk", published by "Industrial Safety & Hygiene News"magazine).

<note tip>An excellent source of news and information about Aviation-related Human Factors is the ”Aviation Human Factors Industry News“. Multiple editions of this online magazine are freely available in PDF (2006-2020). Learn from the mistakes of others.</note>

Are nonconformities resulting from Human Factors "Common Cause" or "Special (Assignable) Cause" Variations?

The answer depends on whether an assignable cause can be identified. In the majority of cases, an assignable cause does not exist. In this case, the nonconformity should be evaluated to determine whether the current risk controls are within an acceptable risk tolerance (established by the company). If not, then there may be additional risk controls that can be put into place to mitigate the risk to an acceptable risk tolerance.

However, if there is an assignable cause… then it may be possible to implement “error proofing” (aka “Poka Yoke”) to eliminate the risk of a recurrence (i.e., a corrective action).

”Lean Factories“ has a web page titled “60 Common Examples of Poka Yoke” at:

https://leanfactories.com/poka-yoke-examples-error-proofing-in-manufacturing-daily-life/

MANY of the “Poke Yoka” examples provided by ”Lean Factories“ do not actually eliminate defects/nonconformities, but rather mitigate the risk of defects/nonconformities. And for that reason, are still valuable examples.

Be sure to distinguish between “Risk Mitigation” actions and true “Error Proofing”. For example

| Action | “Risk Mitigation” or “Risk Elimination” |

|---|---|

| Fuse box lock-out procedures so that power cannot be turned on before an electrical repair is complete and all personnel are out of harm's way. | Risk Mitigation (because workers can fail to follow a procedure) |

| Guide pins to guarantee proper alignment. | Error Proofing |

| Color-coding of components that otherwise look similar. | Risk Mitigation (because workers can still make mistakes. |

| Bins of parts that are electronically connected to the bill of materials through a bar code scanner, so that only the proper bin door opens for a given product. | Error Proofing |

One of the most common failed attempts at error proofing we see appears in documents, e-mails & text messages. Of course, I'm speaking of the auto-spell correction. These have resulted in some hilarious memes. These are much better described as “risk mitigation” controls.

What about "Zero Defects"?

It is surprising that a common topic of debate between quality professionals is whether the “Zero Defects” concept is valid.

“Zero Defects” is a motivational management approach that first appeared in the “Quality and Reliability Assurance Handbook – A Guide to Zero Defects” (4155.12H) published by the U.S. Department of Defense on November 1, 1965, which explained: “Zero Defects is a motivational approach to the elimination of defects attributable to human error”. And: “Zero Defects is dedicated to preventing defects by detecting and removing the causes of their generation. This is an attempt to reverse the unquestioning acceptance of human error as a normal byproduct of personal effort”.

However, the “Zero Defects” concept didn’t gain widespread popularity until it was promoted by Philip B. Crosby in his book “Quality is Free” (1979). Crosby is credited with having developed the “Zero Defects” concept during the early ‘60s while working at the Martin Company as the quality control manager overseeing the Pershing missile program.

This is diametrically opposed to the philosophy and teachings of W. Edwards Deming, who repeatedly showed that, no matter how vigilant the employees, every process contains inherent (i.e., natural “Common Cause”) variations resulting in defects. This was most popularly demonstrated through Deming’s “Red Bead Experiment”. In fact, point 10 of Deming's 14 points specifically rejects the “Zero Defects” concept, stating: ”Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force“.

When performing causal analysis, we must be able to identify and link an “assignable cause” to a problem in order to have a “root cause”. “Assignable Causes” can often be eliminated (e.g., through corrective action). However, when unable to identify and clearly link an “assignable cause” to a problem, we must recognize and acknowledge that those variations are most likely inherent to the process and cannot be eliminated; without completely re-engineering that process. And re-engineering a process may be cost-prohibitive… or impossible (e.g., due to technical constraints/limitations). However, there are usually risk controls we can institute to mitigate the likelihood/probability and/or consequences/impacts of these problems to an acceptable risk tolerance level.

Ultimately, the “Zero Defects” management approach should have been abandoned long ago. Unfortunately, this delusional concept has persisted well into the 21st century!